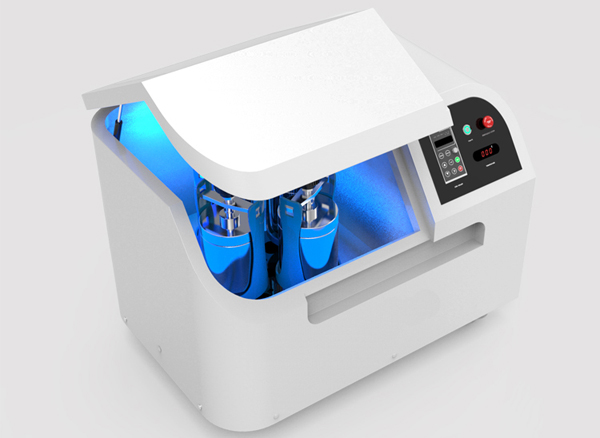

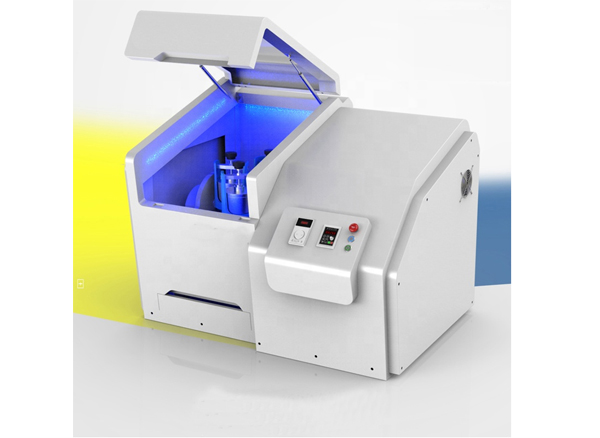

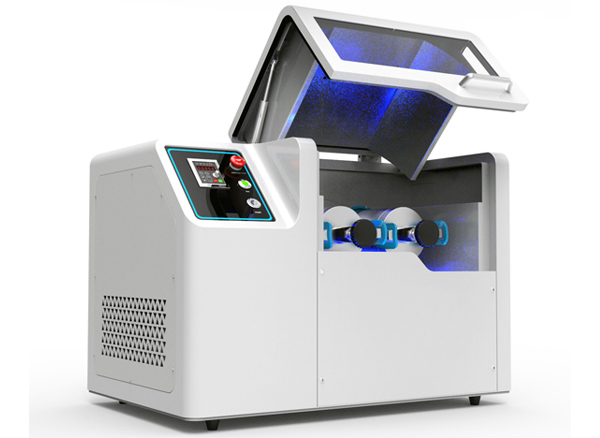

16L Vertical Planetary Ball Mill

Mã: BlueF-P16L

|

Technical Data |

|

|

Model: |

BlueF-P16L |

|

Cat No: |

F-P16L |

|

Working principle: |

Impact, friction force |

|

Applications: |

Pulverizing, mixing, homogenizing, colloidal milling, mechanical alloying |

|

Feed material: |

Soft, hard, brittle, fibrous - dry or wet |

|

Max. feed size (depends on material): |

10mm |

|

Final fineness (depends on material): |

<100nm |

|

Max. sample quantity: |

7200ml |

|

Rotational speed (main disk): |

250r/min |

|

Rotational speed (jars): |

500r/min |

|

Transmission ratio (disk / jars): |

1:2 |

|

Grinding modes: |

16 modes programmable |

|

Grinding tools: |

Grinding jars and grinding balls |

|

Materials of the grinding jars: |

SS304, SS316, nylon, PTFE, agate, zirconia, alumina, PU, WC |

|

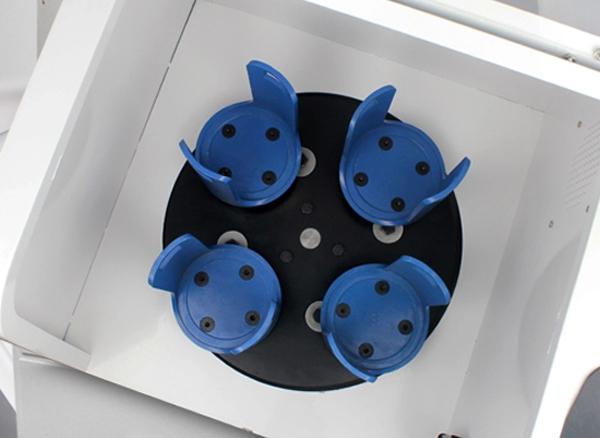

Number of grinding stations: |

4 or 2 |

|

Ball mill type: |

Vertical |

|

Compatible grinding jars: |

1000ml/1500ml/2000ml/3000ml/4000ml |

|

Materials of milling balls: |

SS, agate, zirconia, alumina, nylon, PTFE |

|

Grinding ball diameter: |

3/5/10/15/20mm |

|

Compatibal ball weight |

1600-8000g |

|

Grinding process: |

Dry/wet grinding |

|

Vacuum grinding: |

Yes |

|

Electrical details: |

220/380 VAC, 50/60 Hz, 1.5 KW |

|

Plug types: |

GB/EU/US/UK standard |

|

Net weight: |

269kg |

|

Dimensions (W x D x H): |

978*690*658mm |

|

Noise level: |

50dB |

|

IP rank: |

IP30 |

Overview

Planetary Ball Mills are used wherever the highest degree of fineness is required.

Apart from the classical mixing and size reduction processes, the mills also meet all the technical

requirements for colloidal grinding and have the energy input necessary for mechanical alloying processes. The extremely high centrifugal forces of planetary ball mills result in very high pulverization energy and therefore short grinding times.

Application

· Geology and Mineralogy

· Ceramics

· Chemistry

· Biology

· Pharmaceuticals

· Metallurgy

· Material Technology

· Sample Preparation For Analysis

Features

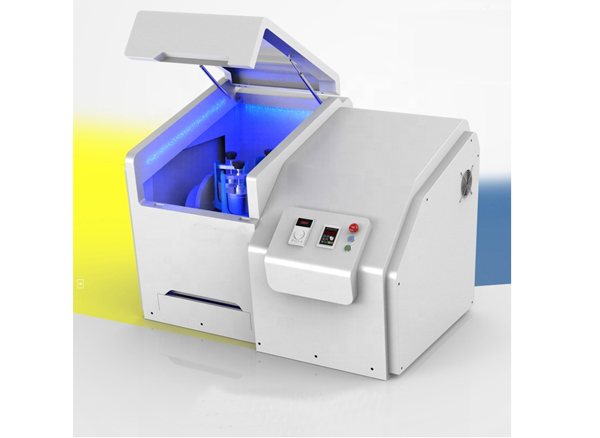

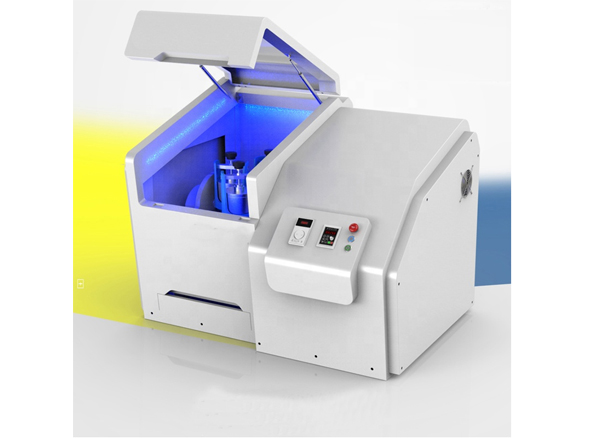

· Elegant design, easy to operate

· Ideal for wet or dry grinding application

· Automatic and programmable control with LED display

· Multiple grinding modes to choose

· High uniformity and excellent repeatability

· Fast rotational speed, high efficiency and fine granularity

· Digital display of the actual rotational speed of the grinding jar

· Four samples with different sizes and materials in one experiment

· Programmable interval and pause times and grinding sequences

· Stepless speed regulation, reversing function

· Smaller grinding jars also possible with an adapter

· Gear-drive offers an effective solution to problems caused by belt driving

· Grinding chamber with forced air ventilation